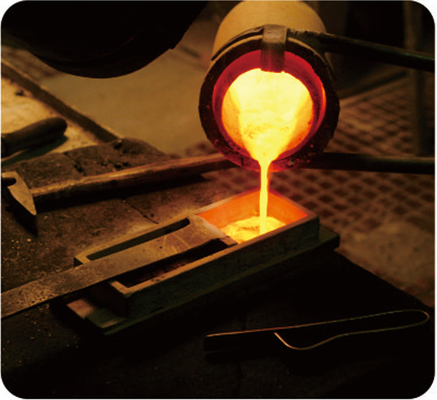

Sprzęt do topienia indukcyjnego do topienia stali / żelaza / miedzi / aluminium / metali szlachetnych

Główne cechy

1, Nagrzewnica indukcyjna średniej częstotliwości przyjmuje technologie kontroli konwersji częstotliwości IGBT w stanie stałym, ma wszystkie rodzaje kontroli ochrony, dając sygnał w warunkach nadmiernego prądu, niedoboru wody, przegrzania, przepięcia, zwarcia i braku fazy , niezawodność jest znacznie zwiększona.

2, ma funkcję wyświetlania prądu, napięcia i czasu, dzięki czemu warunki pracy są łatwo zauważalne i dają wskazówki dotyczące projektowania cewki indukcyjnej, kontroli pojemności.

3, mały rozmiar, niewielka waga, wymaga nie więcej niż 1 m2 i jest ruchomy.

4, ciągłe bicie zdolności przez 24 godziny.

5, Niskie zużycie energii, z możliwością szlifowania elektromagnetycznego, zapewniające równomierne wytapianie.

6, lepsza penetracja ogrzewania i równomierna temperatura wewnątrz topiącego się metalu.

7, Zgodnie z mocą urządzenia i wagą topienia, ogólnie czas topienia 30 ~ 50 minut/piec. Przy pełnym ochłodzeniu pieca, czas nagrzewania 50 ~ 60 minut. Gdy piec jest gorący, czas nagrzewania 20 ~ 30 minut.

Porównaj z topieniem innych urządzeń

1, piec oporowy VS

a, Wysoka sprawność cieplna, szybko topi się.

b, mały rozmiar, oszczędność energii 30%.

c, Odporność lub zapasy z węglika krzemu łatwe do uszkodzenia.

2, VS Węgiel, gaz, piec na olej napędowy

a, Ułatwienie składu i temperatury roztworu regulacyjnego, bąbelek odlewni mniej niż 1/3 do 1/4, szybkość odrzucenia w dół od 1/2 do 2/3, dzięki czemu odlew ma wyższą wytrzymałość mechaniczną;)

b, Zmniejszono utlenianie spalania;

c, topienie indukcyjne może stopić złom z przetwarzania i małe kawałki ze względu na efekt mieszania elektromagnetycznego. Zmniejszenie kosztów materiałów. Zmniejszenie zanieczyszczenia środowiska; hałas jest znacznie poniżej wysokiego sprzętu. Poprawiona została intensywność pracy pracowników i warunki pracy;

d, Tygiel żeliwny stosowany w piecu węglowym i gazowym jest szkodliwy dla stopu aluminium poprzez zwiększenie zanieczyszczenia.Tygiel grafitowy stosowany w topieniu indukcyjnym bez takich wad.)

3, VS SCR lub piec do topienia częstotliwości

a, Wysoka sprawność cieplna, szybko topi się.

b, Mały rozmiar, oszczędzaj energię powyżej 20%.

c, efekt mieszania elektromagnetycznego jest niewielki, więc żywotność tygla jest przedłużona.

d, Regulując częstotliwość w celu uzyskania regulacji mocy, dzięki czemu szybkość topienia jest szybka, elementy materiałowe spalające się mniej i lepiej oszczędzają energię, w szczególności ogrzewanie stali nierdzewnej, miedzi, krzemu, aluminium i innych materiałów niemagnetycznych, zmniejszając w ten sposób koszt odlewu.

Specjalna notatka

1, maks. Szybkość topienia: obliczona na podstawie drugiego tygla;

2, rozmiar tygla oznaczony jako trzymający wagę miedzi;

3, Zużycie energii elektrycznej zależy od jakości materiału, działania operatora i napięcia sieci.

4, takie jak sprzęt do topienia aluminium o mocy 70 kW, koszt topienia 1T.

a 70% pieca do topienia oporowego

b, 70% pieca do topienia częstotliwości

c, 60% pieca do topienia oleju napędowego

d, 80% pieca do topienia SCR

Parametr techniczny

| Rodzaj |

Stal lub lron |

Miedź lub metale szlachetne |

| Piec do topienia 15KW |

- |

5-10kg |

| Piec do topienia 25KW |

4-8 kg |

10-20 kg |

| 40KW piec do topienia |

10-14kg |

20-30kg |

| Piec do topienia 60KW |

18-22 kg |

40-50 kg |

| Piec do topienia 70KW |

25kg |

60-80kg |

| Piec do topienia 80KW |

40kg |

80-100kg |

| Piec do topienia 100KW |

50kg |

100-150kg |

| Piec do topienia 160KW |

100kg |

150-200kg |

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!